Description

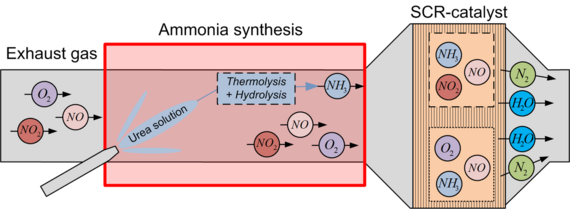

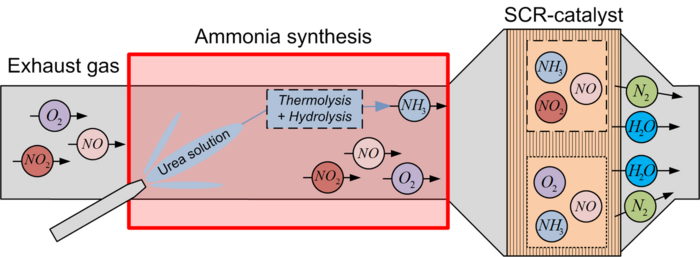

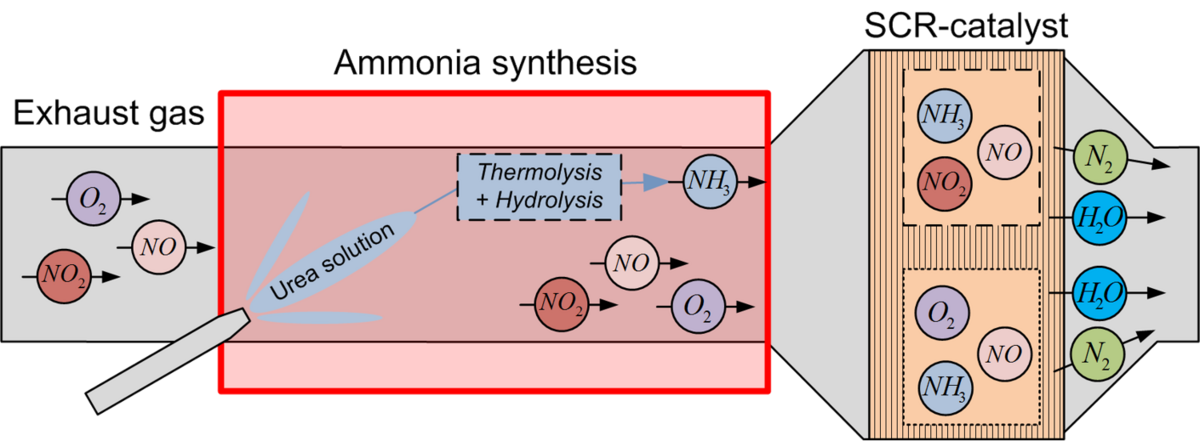

SCR is basically divided into the injection process and the subsequent chemical reaction. The test bench contains an oil burner capable of supplying a hot gas flow of up to 500°C at a maximum of 10 bar. The downstream measuring section has a modular design so that injector configurations, mixing elements and optical access points can be freely selected. This allows detailed optical measurement of the injection process from close to the nozzle up to 3 m behind the nozzle, while simultaneously investigating the chemical reactions by spectroscopic analysis of the exhaust gas composition.

A variety of measurement techniques can be used to investigate the SCR process. Optical analysis of spray parameters such as spray angle, flow field, droplet size and velocity can be carried out using shadowgraph, PIV, Mie imaging or PDA, while a Fourier transform infrared spectrometer is available to measure the chemical components in the exhaust gas. All these measurement techniques provide a suitable basis for evaluating issues such as the influence of pressure and temperature on ammonia synthesis, optimised geometries for urea injection or the effect of mixing elements.

Technical data

| Thermal output | 500 kW |

| Flow velocity | up to 20 m/s |

| Temperature range | 200-500 °C |

| Pressure range | up to 10 bar |

Contact Person

30823 Garbsen