Transparente Einspritzdüsen

© Institut für Technische Verbrennung

© Institut für Technische Verbrennung

| Team: | Dipl.-Ing. Lennart Thimm, Dr. Noritsune Kawaharada |

| Year: | 2017 |

Die Brennstoffzuführung mittels einer Direkteinspritzung in den Brennraum hat sich im Motorenbau inzwischen sowohl für den diesel- aus auch ottomotorischen Bereich durchgesetzt. Die Gemischaufbereitung ist dabei von besonderer Bedeutung für den Wirkungsgrad der Energieumsetzung des Motors und der dabei entstehenden Emissionen.

Bei der Optimierung von Einspritzsystemen rückt die Einspritzdüse selbst immer weiter in den Fokus der aktuellen Forschung. Die Geometrien innerhalb der Düse haben einen großen Einfluss auf das austretende Spray. Ein tiefergehendes Verständnis für die Vorgänge innerhalb der Einspritzdüse ist daher für die Motorenentwicklung elementar.

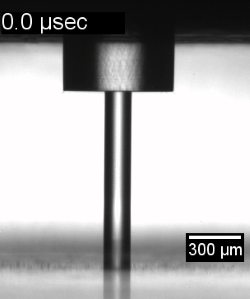

Der Kraftstoff wird je nach Anwendung mit über 2000 bar durch Spritzlöcher von unter 100 µm Durchmesser eingespritzt. Die dabei relevanten Vorgänge spielen sich in sehr kurzen Zeitbereichen von zum Teil weniger als einer Millisekunde ab. Sie stellen somit eine große Herausforderung für die numerische Simulation und die Messtechnik dar.

Im Projekt „Düseninnenströmung“ wird mit transparenten Einspritzdüsen an diesem Problem gearbeitet. Diese Einspritzdüsen erlauben es, bildgebende Highspeedmesstechniken zur Untersuchung der verschiedenen auftretenden Phänomene innerhalb der Düse einzusetzen. Eine besondere Rolle spielen dabei Kavitationsblasen innerhalb der Düse, welche durch die extremen Strömungsbedingungen auftreten. Ziel ist es hierbei, bei realistischen Einspritzdrücken und Düsenformen mehr Erkenntnisse über die Strömung innerhalb des Injektors zu gewinnen.

Darüber hinaus werden numerische Simulationen unter den gleichen Einspritzbedingungen wie in transparenten Düsenexperimenten verwendet, um die Grenzen aktueller Simulationsmodelle und Anforderungen an neue Simulationsmodelle zu verifizieren. Diese Ergebnisse werden in Zukunft eine offene Datenbank für die Validierung und Entwicklung von Simulationsmodellen sein.