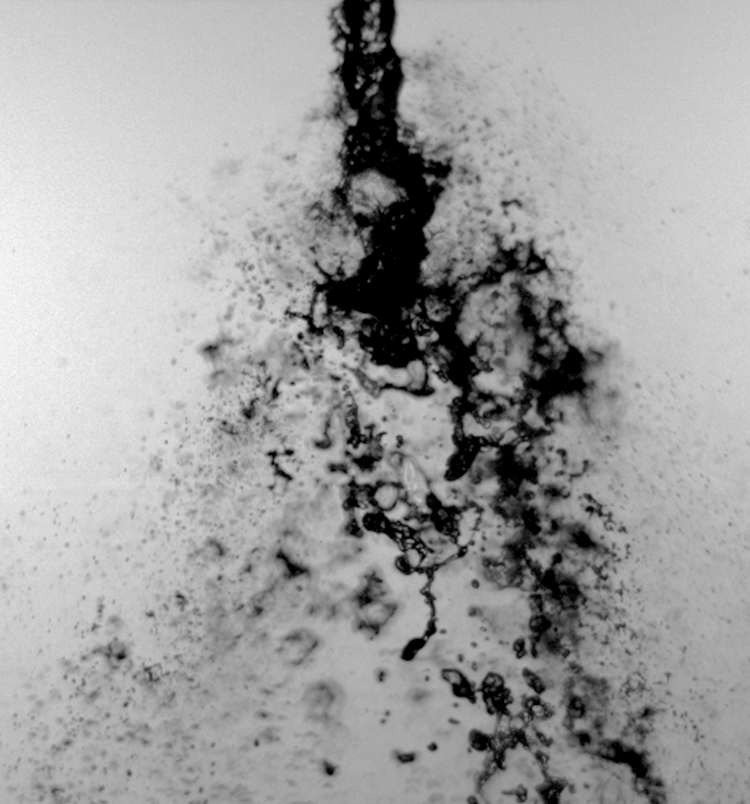

Spray-Einspritzung an Zweistoffdüsen

© Institut für Technische Verbrennung

© Institut für Technische Verbrennung

| Team: | M.Sc. Dipl.-Ing. (FH) Markus Höltermann; Jan Wichmar, M.Sc. |

| Year: | 2018 |

Der Sprayprüfstand besteht aus einer Rahmenkonstruktion, die einerseits die zu untersuchende Düse aufnimmt und andererseits Platz zur Installation der einzusetzenden optischen Messtechnik bietet. Die Düse kann über ein Linearsystem in der horizontalen Ebene, d. h. quer zur Sprayachse automatisiert verfahren werden. Die Einstellung des Abstandes zur Düse erfolgt manuell über eine Spindel. Bei Bedarf kann die Düse in einer optisch zugänglichen Kammer eingebaut werden.

Am Prüfstand können verschiedenen Messtechniken zur Charakterisierung der Sprays eingesetzt werden. Schattenwurfverfahren oder direktes Imaging können genutzt werden um makroskopische Spraykonfigurationen zu ermitteln. Tropfendurchmesser können mit hochauflösender Schattenurftechnik gemessen werden und transiente Vorgänge des Sprayaufbruchs können mit Hochgeschwindigkeitsaufnahmen untersucht werden. Des weiteren kann ein Phasen-Doppler Anemometer (PDA) zur Messung von Tropfendurchmessern und -geschwindigkeiten eingesetzt werden. Hiermit können insbesondere auch Zweistoffdüsen, wie sie in der Luftfahrt oder für die Zudüsung von Harnstofflösungen für die Abgasnachbehandlung von Schiffsmotoren eingesetzt werden, untersucht werden.