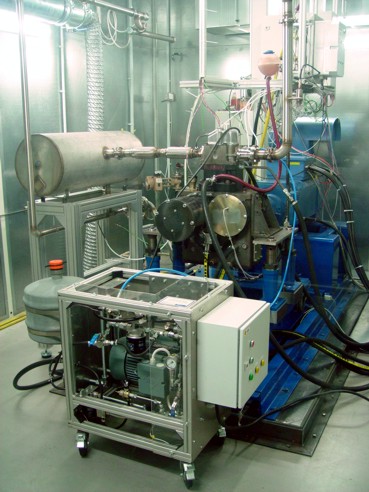

Einzylinderforschungsaggregat zur gasmotorischen Brennverfahrensentwicklung

© Institut für Technische Verbrennung

© Institut für Technische Verbrennung

| Team: | Dipl.-Ing. Sabine Dohrmann, Dr.-Ing. Hauke Hansen |

| Year: | 2013 |

In der heutigen Zeit nimmt der Einsatz von regenerativen Kraftstoffen einen immer größer werdenden Stellenwert ein. Allerdings liegt auch hier ein Augenmerk auf der Einhaltung der stetig strenger werdenden Emissionsvorschriften, sowie der Kraftstoffeffizienz. Um diese Anforderungen einzuhalten, muss das Brennverfahren grundlegend angepasst werden. Eine Besonderheit stellen dabei die Brennverfahren von Gasmotoren dar, welche am Institut untersucht werden.

Hierzu steht ein Einzylinderforschungsaggregat basierend auf der Mercedes Benz Baureihe 500 mit einem nutzfahrzeugtypischen Hubvolumen von zwei Litern zur Verfügung. Für den Betrieb im Dual-Fuel-Betrieb wurde ein modernes Common-Rail-Einspritzsystem adaptiert und die Brennraumgeometrie angepasst. Das Gas wird während des Ansaugtakts in das Saugrohr eingedüst und gegen Ende des Verdichtungstakts mittels Diesel-Pilot-Einspritzung gezündet.

Sämtliche Betriebsmedien sind extern konditioniert, wodurch eine optimale Reproduzierbarkeit der motorischen Randbedingungen gewährleistet wird. Sowohl der Kraftstoffpfad als auch die Luft- und Abgasstrecke sind auf maximale Variabilität ausgelegt. Um diese Prozessgrößen simultan und hochpräzise regeln zu können, kommt ein Steuergeräteverbund zum Einsatz, welcher ein flexibles Motormanagement darstellt. Dies bildet nicht nur eine optimale Messumgebung, sondern erlaubt auch eine schnelle Adaption von neuen Messgeräten oder geänderten Motorparametern.

Aktuell wird im Rahmen eines öffentlich geförderten Forschungsprojekts der FNR (Fachagentur für Nachwachsende Rohstoffe) am ITV in Kooperation mit dem Öl-Wärme-Institut Herzogenraht ein neuartiges Dual-Fuel Brennverfahren entwickelt, welches darauf abzielt, auch ungereinigte Biokraftstoffe in aufgeladenen Motoren einzusetzen und gleichzeitig die Schadstoffemissionen zu reduzieren. Der technische Ansatz zum Erreichen dieser Ziele besteht darin, den Kraftstoff in einem dem Motor vorgelagerten Reaktor zunächst zu einem homogenen Gemisch zu verdampfen und dieses im Brennraum durch eine kleine Menge Diesel zu zünden (Diesel-Pilot-Einspritzung). Für die Eindüsung des Gases in den Brennraum werden verschiedene Konzepte erarbeitet und getestet.

In Zukunft kann dieser Motorprüfstand auch für andere Gasmotorische Brennverfahrensentwicklung eingesetzt werden, beispielsweise um Einmischprozesse oder Dual-Fuel-Konzepte zu untersuchen.

Am Institut steht weiterhin ein nahezu baugleicher optisch zugänglicher Forschungs-Einzylindermotor zur Verfügung. Dies bietet die Möglichkeit, mit entsprechender optischer Messtechnik auch die räumlich und zeitlich aufgelösten Vorgänge der Gemischbildung, Zündung und Verbrennung bei solchen Brennverfahren zu untersuchen.