Prozesse der Kraftstoffzerstäubung und Auswirkungen der Düseninnenströmung

© Institut für Technische Verbrennung

© Institut für Technische Verbrennung

| Team: | Dr. Noritsune Kawaharada |

| Year: | 2018 |

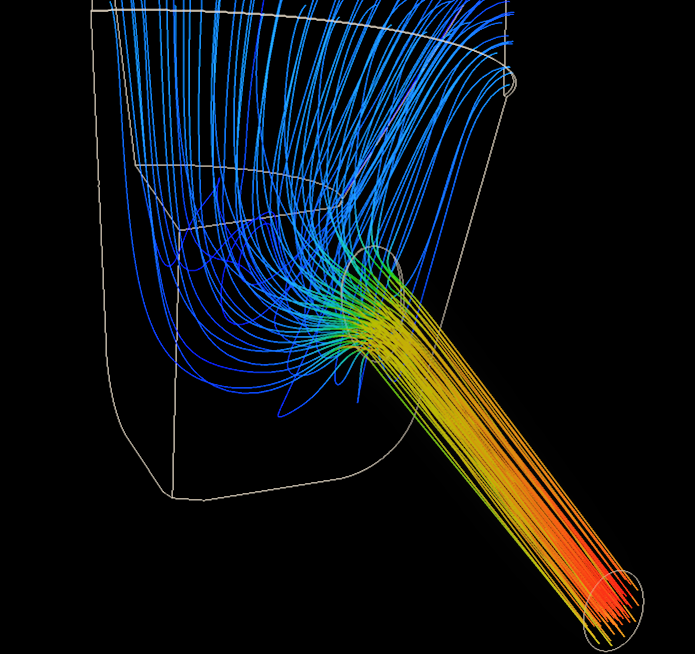

Die Hochdruckeinspritzsysteme werden üblicherweise in Verbrennungsmotoren verwendet. Eingespritzter Kraftstoff bildet ein Spray und bestimmt Effizienz und Emissionen der Motoren. Trotz der Wichtigkeit der Sprühentwicklung werden die physikalischen Prozesse, insbesondere im Nahfeld der Düse aufgrund der komplexen Kombination von Phänomenen nur in einem Teil davon verstanden. Bekannte Messtechniken sind aufgrund der geringen Abmessungen (< 100 µm), der kurzen Injektionsdauer (< 1 ms) und des dichten Sprays (ca. 100000 Tropfen in 1 mm3) nahezu unmöglich anzuwenden, um Informationen über Zerstäubungseigenschaften in nahen Düsen zu erhalten. Daher wird derzeit eine fortschrittliche Lasermesstechnik entwickelt, die ein Mikrosondenvolumen und eine ultraschnelle Abtastrate (GHz) aufweist. Die Technik ermöglicht es die Eigenschaften der Sprühtröpfchen zu untersuchen. Die Eigenschaften werden durch die Phänomene in der Düse, beispielsweise durch Kavitation und Turbulenz, beeinflusst. Um den Effekt dieser Phänomene auf den Zerstäubungsprozess zu bestimmen, werden numerische Simulationen der Düseninnenströmung parallel zu den Experimenten durchgeführt.